Uso:

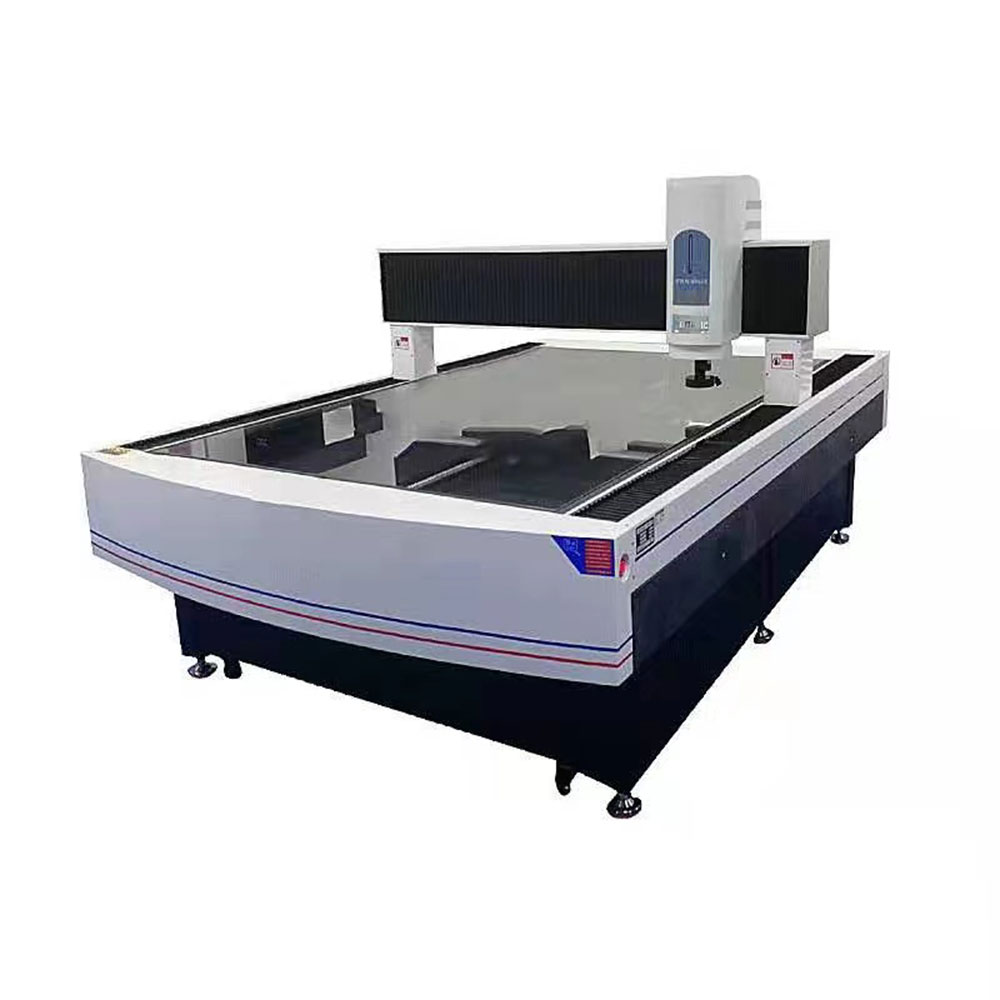

The fully automatic large stroke composite image measuring instrument is suitable for all application fields with the purpose of two-dimensional coordinate measurement. It is widely used in high-end manufacturing industries such as LCD, Pantallas de pantalla LED, touch screens, mobile tablets, large glass products, automotive accessories, large PCBs, film films, televisions, hardware, molds, instrumentos, plástica, precision electronics, precision machinery, etc..

Características del instrumento:

Base de mármol de alta precisión, columns, Asegurar la estabilidad y la rigidez extremadamente altas

Taiwan’s high-precision linear guide rail and grinding grade ball screw

Panasonic fully enclosed servo motor from Japan, with adjustable speed

Imported German Heidelberg RSF high-precision non-contact grating ruler with a resolution of 0.0005mm

Programmable 5-ring and 8-zone circular surface light can meet lighting needs from different angles

Fully automatic zoom lens, Cambiar el aumento no requiere tomar una escala, ahorrar tiempo de calibración y evitar errores humanos

Optional British Renishaw contact probe for 3D data measurement such as height and depth

Optional Japanese KEYENCE laser displacement sensor for tracking and measuring surface features of roughness and flatness

Optional spectral confocal sensor for measuring small and sensitive surfaces

arguments:

| modelo | DMD1512 | DMD2015 | DMD2515 |

| incógnita. Viaje en eje (mm) | 1500*1200 | 2000*1500 | 2500*1500 |

| Z-axis travel(mm) | 200(customizable) |

| incógnita、Y、Z轴分辨率 (μm) | 0.5 |

| length standard | HEIDENHAIN Grating ruler |

| exactitud (μm) | 2.5+L/150 L=The length of the measured workpiece, en unidades:mm |

| instrumentación | Electric, Panasonic servo motor |

| Dispositivo de detección de imágenes | Resolución alta 1/2 “color CCD camera imported from Japan |

| Lente de zoom de marco congelado | 0.7X ~ 4.5x |

| Aumento de video | 23X ~ 190x |

| Object field of view | 10.6mm ~ 1.6 mm |

| work distance | 90mm |

| measuring software | Professional 2D automatic measurement software |

| fuente de luz | Iluminación reflectante | LED circular programmable light |

| Iluminación de transmisión | LED tracking bottom horizontal light |

| fuente de alimentación | AC100 ~ 240V 50/60Hz |

The fully automatic image measurement instrument is an advanced measurement device based on digital image measurement technology, which can achieve high-precision, fast, and non-contact measurement. This instrument is mainly used for size detection and quality control in modern manufacturing, and can meet the needs of modern manufacturing for high-speed and accurate measurement.

El principio de funcionamiento del instrumento de medición de imagen totalmente automático se basa principalmente en la visión artificial y la tecnología de procesamiento de imágenes. Utiliza lentes y sensores ópticos de alta precisión, combinado con tecnología informática y algoritmos de software, Para lograr mediciones rápidas y de alta precisión de varias formas y tamaños complejos. Este instrumento puede medir una gran cantidad de muestras en un corto período de tiempo sin la necesidad de operación manual, greatly improving measurement efficiency and accuracy.

The advantages of a fully automatic image measuring instrument include:

Alta precisión: This instrument uses high-precision optical lenses and sensors, combined with advanced image processing technology, to achieve measurement accuracy at the micrometer or even nanometer level.

Fast: This instrument can complete a large number of sample measurements in a short time, greatly improving measurement efficiency.

Non contact: This instrument adopts a non-contact measurement method, which will not cause damage to the sample, and is particularly suitable for measuring fragile, soft or thin samples.

Automation: This instrument can achieve automated operations, reducing the errors and costs of manual operations.

Repeatability: The measurement results of this instrument have high repeatability, ensuring the accuracy and reliability of the measurement.

The application of fully automatic image measuring instruments is very extensive, including but not limited to the following fields:

Electronics industry: used for size testing and quality control of electronic components, integrated circuits, and flat panel displays.

Automotive industry: used for size inspection and quality control of automotive components, brake pads, tires, etc..

Hardware industry: used for size inspection and quality control of metal parts, screws, nuts, bearings, etc..

Medical devices: used for size testing and quality control of medical equipment, surgical instruments, and implants.

Precision manufacturing: used for size inspection and quality control of precision machinery, cutting tools, molds, etc..

Research field: used for high-precision measurement and analysis in materials science, biomedical, geological and other fields.

En resumen, the fully automatic image measuring instrument is a very important modern measuring instrument with broad application prospects and huge market potential.